Cold Weather = Cold Fuel

Oct 13, 2020

As much as I hate to admit it,

a South Dakota winter is just around the corner. With the 70-degree temps we have seen lately, it is hard to think about it. Unfortunately, along with cold temps comes issues with your equipment. It seems like anything that might (or could) go wrong shows up on the coldest and/or busiest day of the year, starting with your diesel fuel. With the warm weather, nobody wants to think about winter diesel. But it is time.

Depending on where you are with harvest or fall tillage, and if you switch from #2 to #1 using the same tank, your next order will want to be some form of a blend to get the process started. It is also very important to keep in mind that #1 and #2 need to be blended at a minimum temp of 24 degrees or the fuel will not stay in suspension. Also keep in mind the 24 degrees is fuel temp, not air temp.

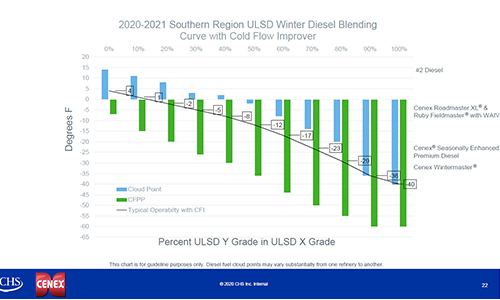

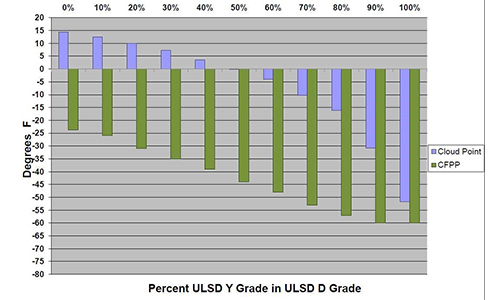

A couple of terms to be familiar with

Cloud Point. This is the temp at which diesel starts to form wax crystals in the fuel possibly causing flow issues.

CFPP or Cold Filter Plugging Point. This is the temp at which fuel “gels” up and will no longer flow through the filter.

When blending fuels, you have several options:

-

You can blend whatever percentages you are comfortable with.

-

CHS has CFI (cold flow improver) which is blended at the terminal when loaded.

-

Straight #1. Keep in mind that the #1’s of today are much different than yesteryear. #1 FM and RM both have the same additive package as #2 FM and RM just in Y (#1) grade fuel.

Other Important Reminders

If you choose to use an off the shelf additive, use the recommended treat rate. If you need 2 glugs, 4 will not make it better. It only worsens the problem.

Last, but not least: FILTERS! When the weather turns cold, change the filters on your pumps.

Below are two charts

One is with CFI added to your fuel the other is just plain blending of #1 and #2.

If you have any questions, don't hesitate to give us a call!

Brian Beck

Energy Department Manager/Safety Coordinator